Flow Chemistry describes the process of a chemical reaction in a continuous flow. Fluids are pumped into a reactor and brought into contact with each other. The flow chemistry process has great advantages in the production of large quantities of a specific chemical product. It is therefore an alternative to conventional batch production.

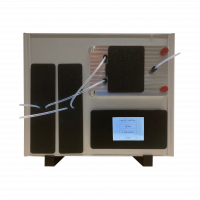

So, what do you need for flow chemistry processes? You just need pumps to move your reagents, a mixing device like a microreactor to combine the reagents and something where the final product goes into.