Little Things Factory GmbH develops and manufactures microreactors made of glass, quartz and glass-silicon compound materials. These materials are ideally suited for microfluidic applications. These materials have many advantages for those applications as they are resistant to difficult environmental influences like high temperatures and dangerous chemicals. At the same time, these materials displays a high degree of biocompatibility.

Customized Reactors

MR LAB Series

MR PILOT Series

HTM Series

XXL Series

Emulsifier

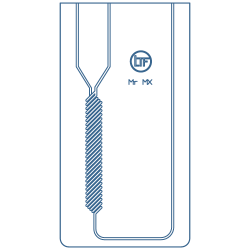

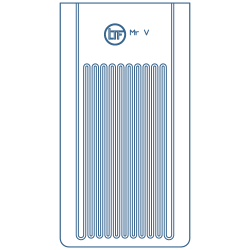

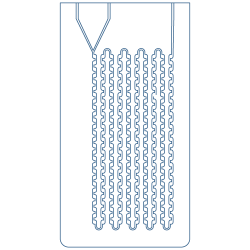

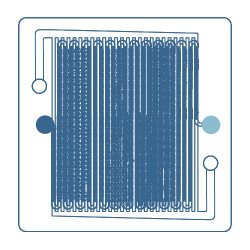

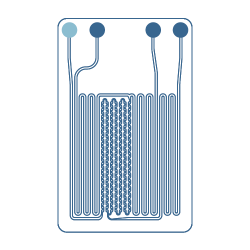

MR LAB Series

The inexpensive MR-Lab series was developed for laboratory syntheses. It permits the simple translation of an intermittent work method into a continuous one using standard laboratory equipment. The temperature regulation is carried out as required in temperature adjustment vessels, on hotplates or in cold mixtures. The microreactors are connected by means of a connecting bar with 1/4“ UNF 28 fittings. An optional additional frame accepts the connection bars together with the reactors. If a constant temperature is required over the entire frame including hoses and reactors, the entire frame can be immersed to the top of the hoses.

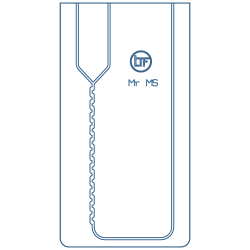

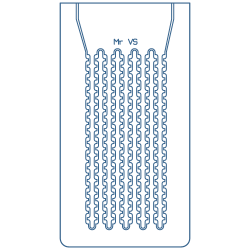

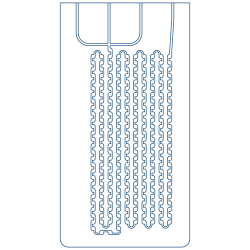

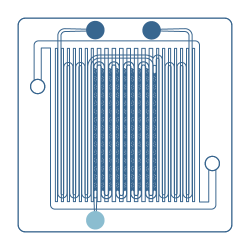

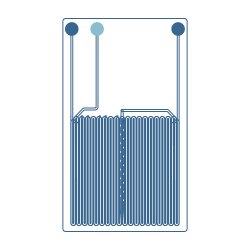

MR PILOT Series

The MR-Pilot series permits the implementation of the results investigated in the lab into bigger scales. As the big brother of the MR-Lab series, MR-Pilot is available with different volumes and can be connected in series to achive higher volumes. The reactors are connected about a connection bar. Like microreactors of the MR-Lab series, temperature regulation is carried out in temperature adjustment vessels, on hotplates or in cold mixtures. Higher stability is individually possible on inquiry.

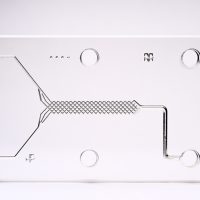

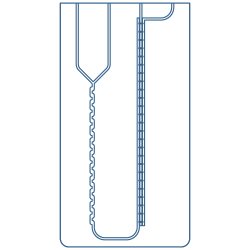

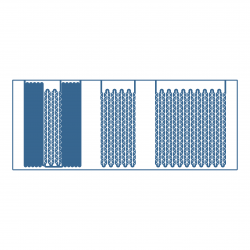

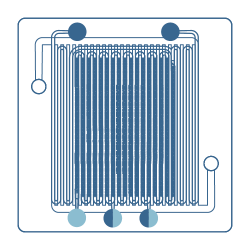

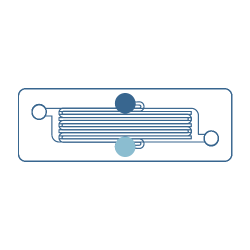

HTM Series

Microreactors of LTF’s HTM series have been developed as an experimental platform. These reactors are available either with or without integrated heat exchangers. The connection is made via 1/4″ UNF 28 bonded glass threads, while the heat exchanger is connected via SWAGELOK fittings.

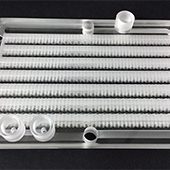

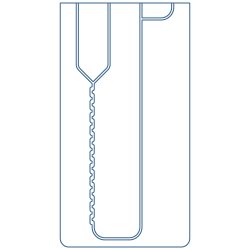

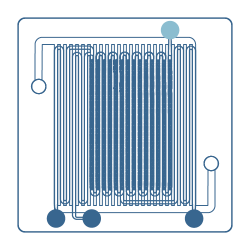

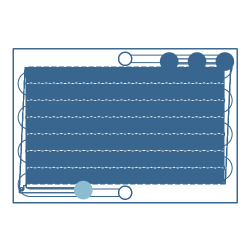

XXL Series

LTF’s XXL series permits the implementation of the results investigated in the lab into production scales. Different types are available which all share a compact construction design. The reactors with integrated heat exchanger are connected via 1/4″ UNF 28 bonded glass threads, while the heat exchanger is connected via SWAGELOK fittings.

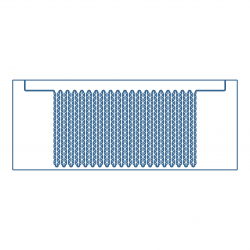

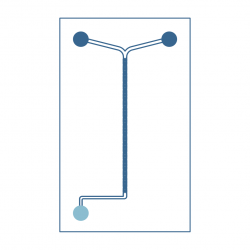

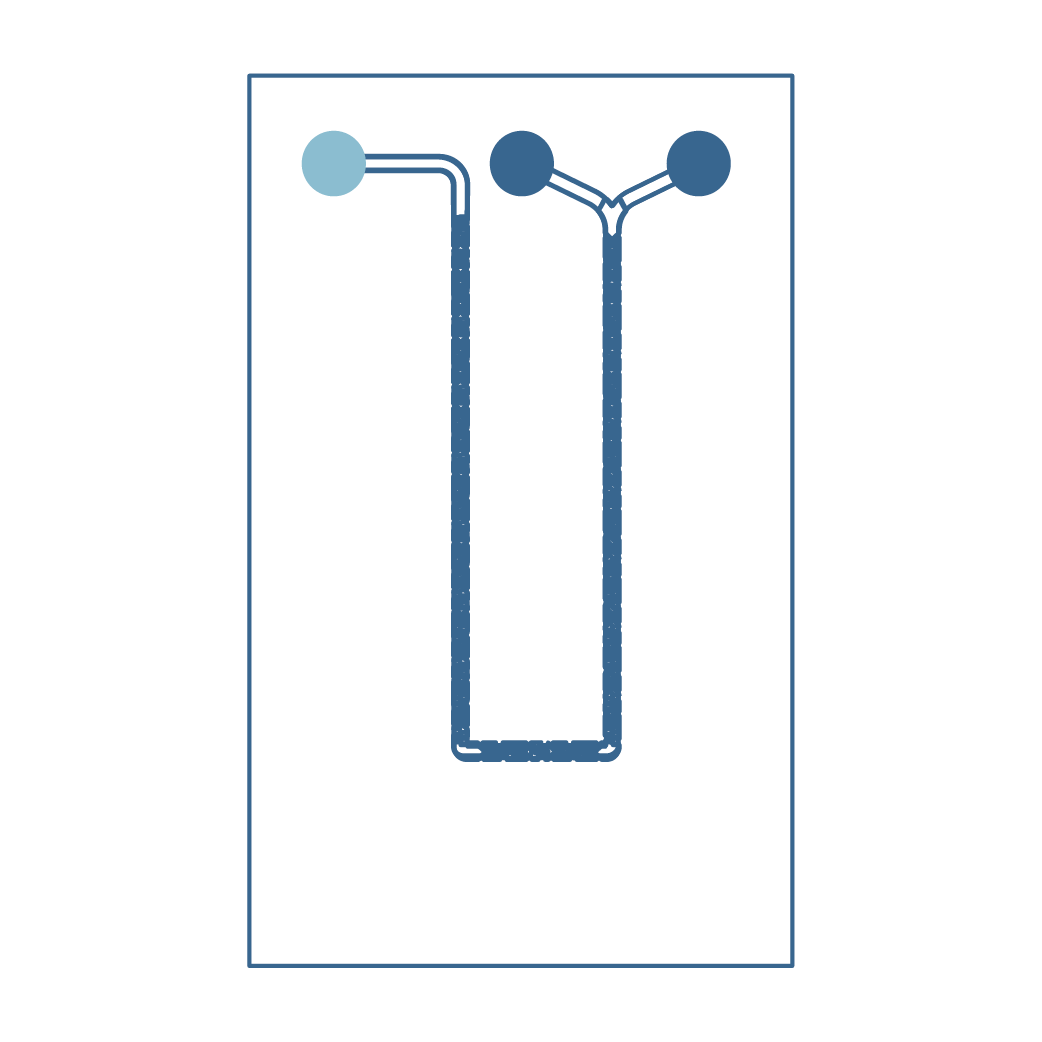

Emulsifier

The LTF emulsifier is a microfluidic system for the simple production of multiphase emulsion droplets, where the droplet size can be controlled by the flow rate. The reactor has an integrated heat exchanger and will be connected via 1/2″ bonded glass threads, while the heat exchanger is connected via SWAGELOK fittings.